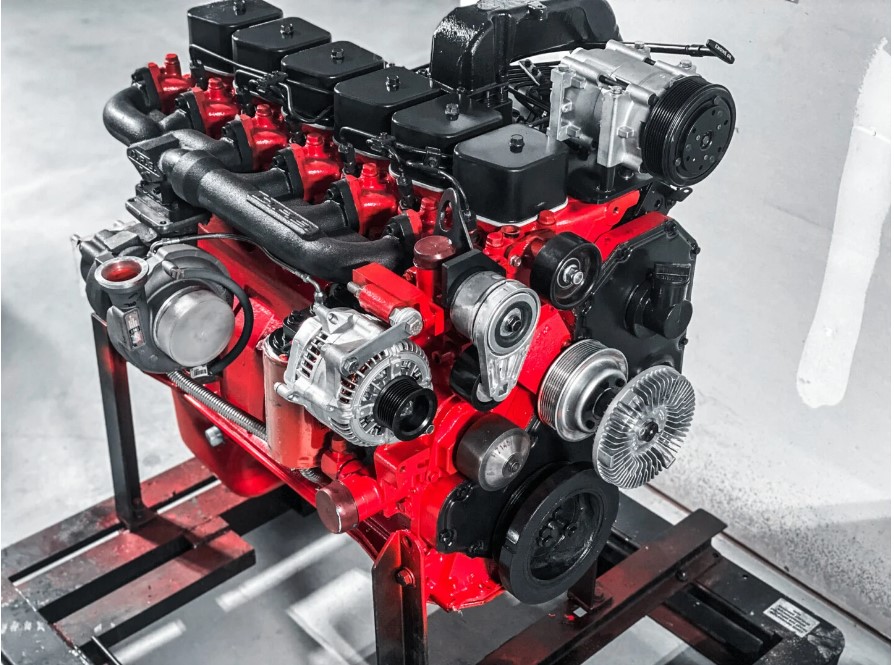

Diesels are known for the distinct sound they make when they run, but, over the years, this sound has begun to become quieter.

The sound made by diesels is due to a condition called “fuel knock”. Fuel knock is used to describe the condition when the fuel that is injected into the cylinder of a diesel engine detonates slightly early. This is a normal condition for diesel engines in considerable amounts, excessive amounts of fuel knock indicate that the fuel injection system is not running properly.

The basic principle of a combustion engine is a piston moving up and down inside of a cylinder, when the piston is sent downward by the explosion of the fuel, this is what drives the engine. Diesel motors do not utilize spark plugs like gasoline engines do, diesel engines instead use air heated to extremely high temperatures using compression. Compression heats the air to these high temperatures by having the piston come extremely close to the cylinder head, essentially the roof of the cylinder. This causes the air to be squeezed to a higher level, heating it.

With the air heated, an injector which is located in the cylinder head sprays diesel at an extremely fine mist into the cylinder. This combination causes the mixture to ignite, sending the piston downwards, the remaining momentum drives the piston back up to restart the cycle. When the fuel is ignited, it is ignited slightly early, meaning that it is ignited as the piston is still driving up in the cycle, giving the distinct knocking sound of the diesel engine.

Older diesels were mechanically controlled, meaning that there was a set point on a high pressure fuel pump that sent fuel to the injector. This meant that the fuel ignited at the same exact point in the cycle each time. Modern diesels adopted the use of computer controlled injection systems, commonly known as common rail systems. The addition of pilot injection came along around the year 2000.

“New engines run much smoother and sound quieter when they idle” stated Junior Jonathan Copeland.

Pilot injection reduces combustion noise by spraying a small amount of the fuel in a pulse before the main pulse. These main pulse is only 0.0007 seconds after the pilot pulse. This small pulse of fuel allows the combustion process to slowly start, then adding more fuel to it to complete the process. This is the reason that modern diesels run with less clattering at lower speeds. This also allows the engine to start easier at extremely low temperatures.

Pilot injection is used only for lower engine speeds, at higher speeds, pilot injection is disabled. The reason for this is that at speeds around 2500 rpm, pilot injection is no longer needed as the engine is at operating speed, the use of pilot injection will create inefficient running conditions.

Pilot injection is one of the many advancements made to diesel engines, allowing for smoother and more efficient operation. This is a step towards better designed and more powerful diesel engines.